How the Mill Works

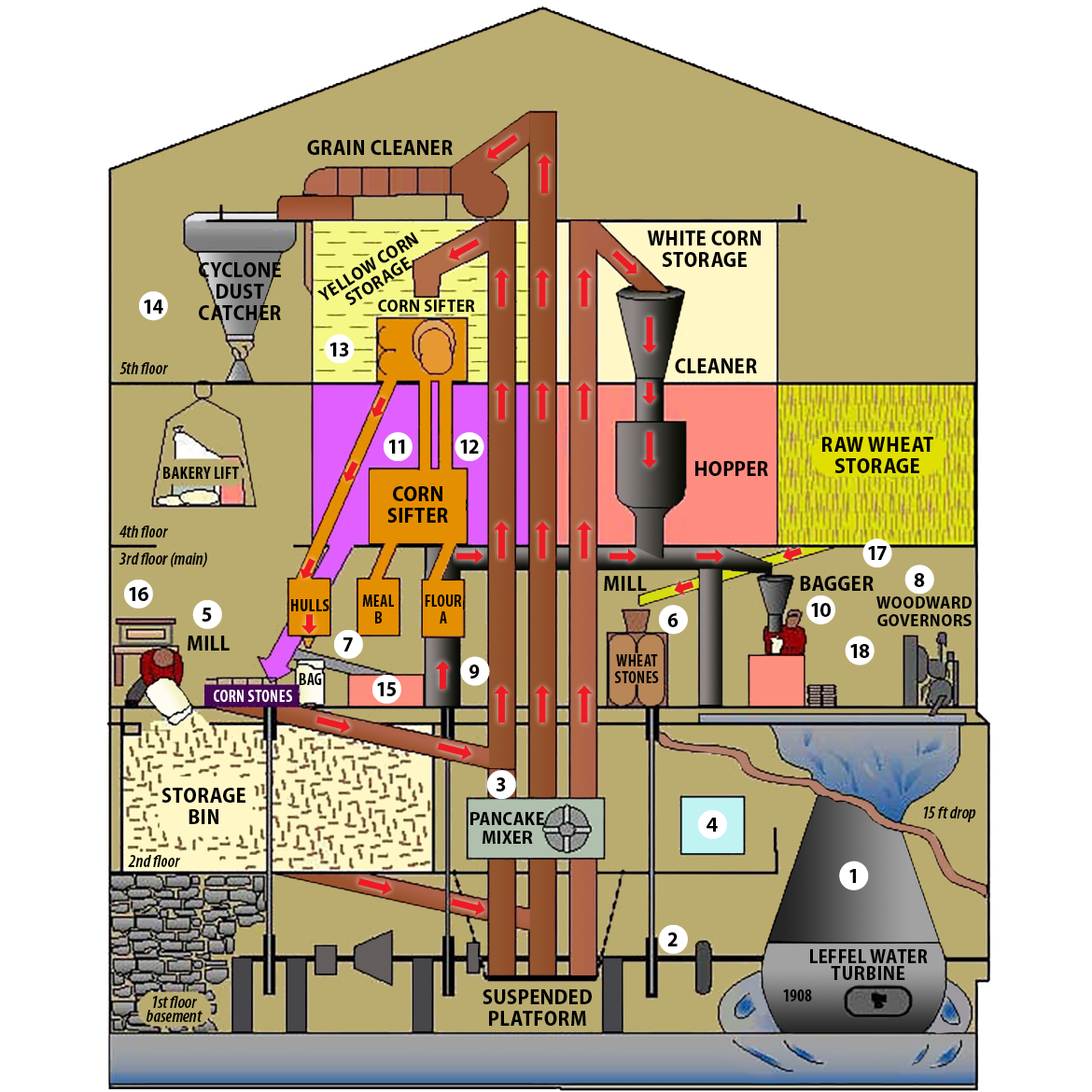

1. The Leffel Water Turbine

The Leffel Turbine is named after James Leffel who founded The Leffel Turbine company in Springfield, Ohio in the year 1861. When this area of the mill burned in 1869, the water wheel was destroyed and since the turbine was relatively new and more powerful, it was installed. The mill’s owners at the time were the Armstrong family.

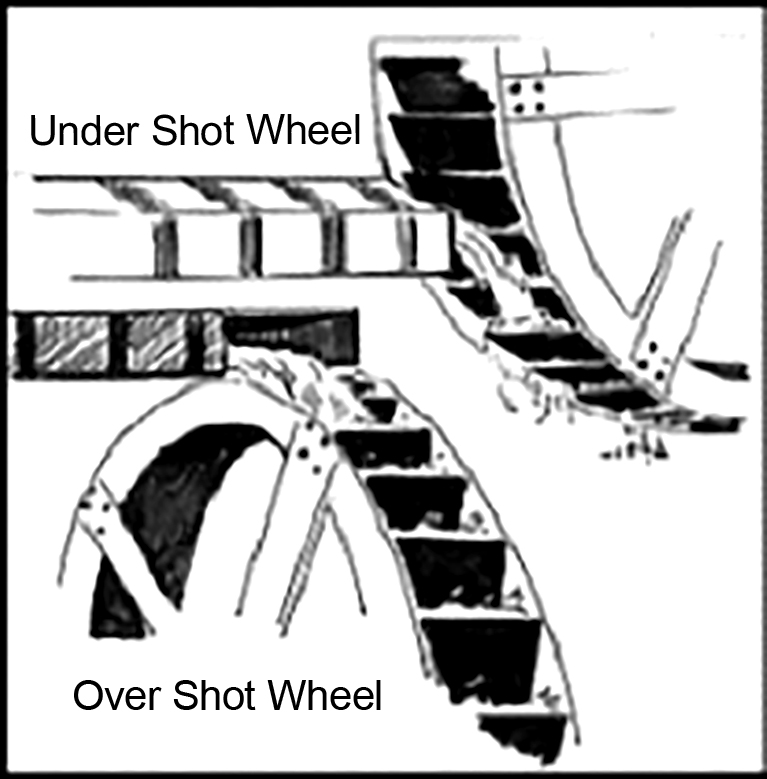

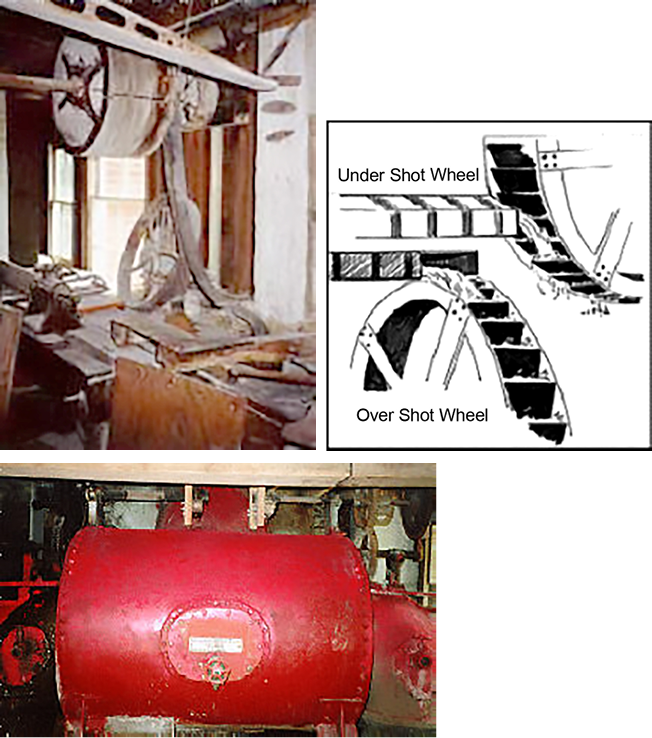

Until then the Historic Clifton Mill used an under shot water wheel, which simply means the water ran behind the lower back side of the wheel. The water wheel that most people think of when they think of old mills is called an over shot wheel.

The turbine at Historic Clifton Mill gets its water supply from a mill race, which is simply a small stream or creek that is made by cutting a channel and diverting water held back by a dam. The Leffel turbine creates almost 300 horse power at 900 RPM. Water from the mill race enters the turbine from the top tube. It passes through valves and paddles which spin them around. The paddles are attached to a piece that holds the main shaft, so when the paddles spin, the shaft spins. The water is discharged through the draft tubes at the bottom. It is these draft tubes which help give the turbine its power or torque. The pull of the water falling down the draft tubes give it more power. The turbine also creates a strong suction from the smaller pipe in the front. This suction power was used in the early days to help vacuum out the mill. On the back side of the turbine there was a strong push of air which was used to cool the place down by blowing the constant air over a block of ice. The water power was also used for the millers work bench area to turn the lathe and table saw. This is pure clean power, the water is not heated or treated in any way.

2. The Main Shaft and Pulley Line

From here all the water power is dispersed through the mill with pulleys and belts.

3. The Pancake Mixer

The pancake mixer was built in the 1800’s. The mixer tumbles and blends all the ingredients that the miller puts in to make our mixes. It has the capacity to do 500 lbs. at a time and takes about 15 minutes to complete this operation. From the mixer the product is moved up by the bucket elevators to the bagging area.

4. The Generator

The Generator was installed in 1908. From 1908 to 1938 the generator ran 24 hours a day to provide electricity for many of the homes of Clifton, Cedarville and Yellow Springs for $1.00 a month.

5. Red Meadows Mill

The 20 inch Red Meadow Mill is the corn grinding mill. It is a Sprout and Waldron French Burr Mill, built in 1889. It has a pair of 20 inch burr stones. French refers simply to where the stone (granite) was quarried. The term burr is the way the stone is cut to help it grind. The stones are inside the red metal housing. The corn enters through the center. One stone is stationary and the other is rotating. The grain is crushed as it moves to the outside of the stones. This mill can grind up to 800 pounds an hour.

6. Gray Meadows Mill

The gray grinder is for our wheat and rye grinding. By adjusting the gap between the two vertical stones, the miller can make cracked wheat or whole wheat at various degrees of coarseness. This Meadows Mill was built in the early 1900’s. The stones inside are 24 inch French Burr stones and can grind up to 1000 lbs an hour.

7. Bulk Corn Product Bagging Area

In this area, the corn is bagged. It is sifted and separated into 3 main products. The chute in the center is where corn meal comes down to be bagged. Corn meal is made from the center of the grain. It may look like it has black specs in it but this is the corn germ, the part of the seed that has the best nutritional value for you. The third chute is for the corn bran. Corn bran has a lot of the hard shell it in and is usually sold off as feed.

8. Woodward Governors

The Woodward governors were installed when theturbine was installed in the late 1800’s. The function of the governors is to control the RPM of the mill to make sure it is running at a good constant speed with enough power to keep grinding. If one set of stones is in use grinding corn and the miller wants to grind wheat on another set of stones at the same time the governors will automatically open up the water gates on the turbine to allow more water to enter the turbine. We still rely on this piece of equipment and it is built to last. When the round handle is turned towards you the mill starts up. It is one of the first things the miller uses.

9. Belt Bucket Elevators

The belt bucket elevators are used for many purposes. These square shafts run from the bottom of the mill to the top floor. They help move the grain to the holding bins for storage and move grain to the grinding area. They also move the ground flour and meal to the sifting, mixing and bagging areas. The belts are moved by the water power that drives the main shaft in the basement.

10. Bulk Bagging Area

In this area we bag up 25 and 50 pound bags of our whole wheat, cracked wheat and rye flour that is ground in the gray mill stone. The products in this area are whole grain. That means that it is not sifted, that the whole grain is in there. For example our whole wheat flour has wheat germ and wheat bran mixed in with the wheat flour. This is the healthiest type of flour. The bread flour and whole wheat pastry flour are ground much finer and are not coarse compared to whole wheat or cracked wheat.

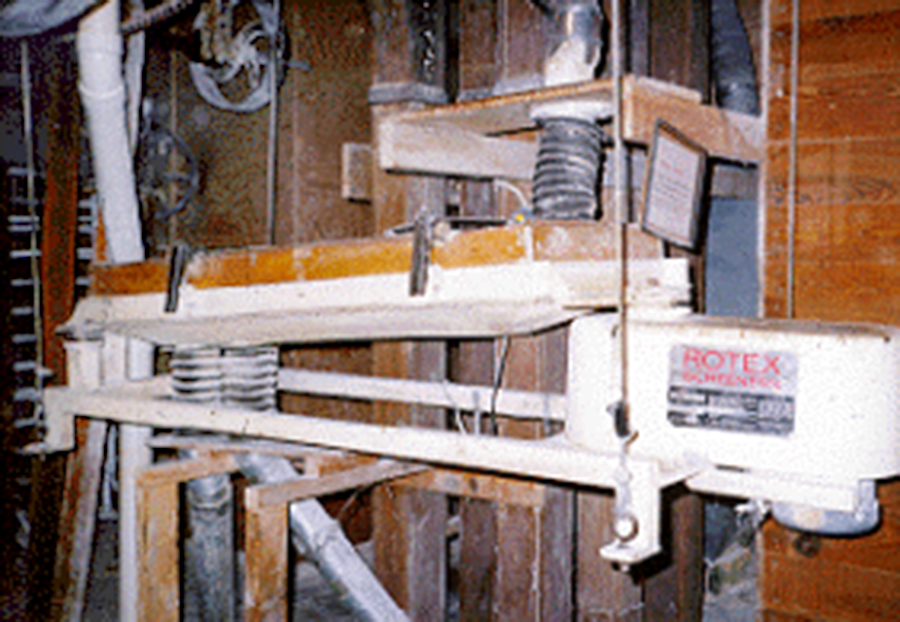

11. The Rotex Sifter

This sifter has been in use for almost 100 years. It is the second sifting phase for the corn. The corn meal and corn flour that were separated from the case sifter above enter the rotex sifter. The rotex sifter then agitates back and forth moving the material over a set of screens, each a different size. One size is very small so only the corn flour passes through. The corn meal then drops through the screen with the larger holes. Each screen level leads to a chute that takes it to the lower floor.

12. Large Storage Bins for Wheat and Corn

Total capacity of storage bins is over 15,000 pounds.

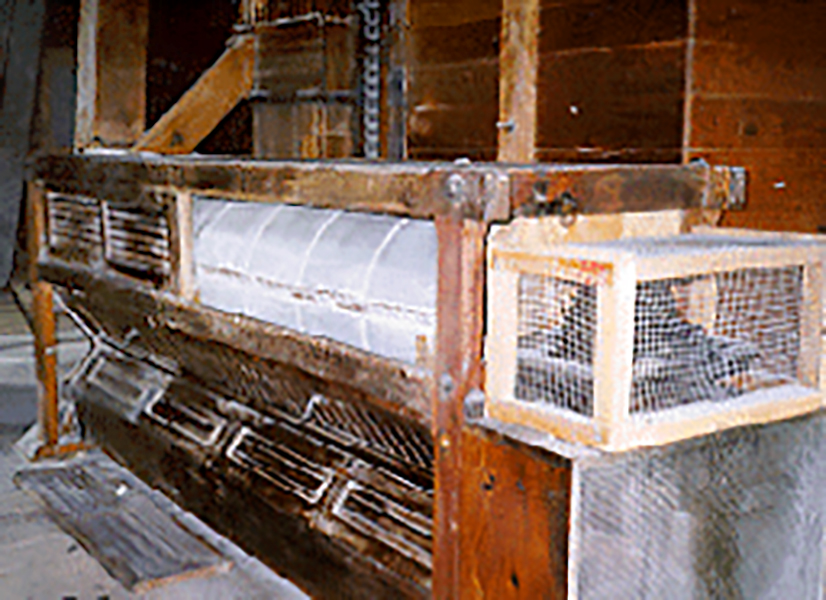

13. The Case Sifter

This sifter is what the mill uses for the first step in the separating process. Once the corn has been ground the buckets and elevators move the ground material into the sifter where the flaky bran and corn hulls are removed. This is done by the material moving across a cylinder covered with screen. The hulls are too big to fit into the holes of the screen. The cylinder spins around letting the corn meal and flour drop through while the hulls are pushed over and down a chute.

14. The Cyclone Cleaner

The cyclone cleaner is used to catch the pieces of corn cob and corn stalk that may be in with the corn when it was brought into the mill from the fields. The grain would move across an area of large metal screens and drop down into a chute that leads to the storage bins. The water power from the mill would spin a set of wooden blades inside the cone shape. This would create a strong draft and suction that would remove dust, dirt, cob and stalks early in the storage process.

15. The Old Stones

Inside this wooden case are the original stones that the mill used back in 1802. They are almost 2 tons in weight and are 48 inches wide. These stones are unique because of the way they are put together. The stones are pieced together like a puzzle to help form a round wheel. The pieces are from the ballast of some of the early ships that came here. There were no quarries then so they used the rock ballast to make the grinding stones. These stones are also made of granite. The stones are set in a horizontal position. The corn drops into the center and is ground up by the weight and motion of the top stone, the “runner”, while the bottom stone remains stationary. The top stone is called the “runner” because it moves while the bottom stone is stationary. These stones are able to grind 400 to 500 lbs of grain. The amount of corn that can enter the stones is controlled by what is called the shoe, which sits on top of the wooden case. As the stones grind at a constant level the vibration is also fairly constant. The vibration helps the shoe shake some corn down to the stone. A small rope on the shoe helps determine how much corn the shoe will drop into the stones. You can see the shaft that powers these stones in the floor below. The miller would check the degree of coarseness by moving the little door at the bottom of the stones base. The miller would open it, stick his hand in and squeeze it to see how much flour there was. He can adjust the stones to make it more or less coarse. Move stones close together and get finer flour, move apart and get coarse.

16. The Hopper Scale

This scale has a dual purpose. It is a small temporary holding bin that is also a scale. This allowed both the farmer and the miller to agree on exactly how much grain there was to store and grind. Once weighed the grain drops to the bottom hole and is moved by belts and buckets either to the large storage bins or redirected to the grinding area.

17. The Main Beams

The main beams that you see in the mill are from trees that were cut down right here. The early builders used local trees to build all of the mills along this river. There were at least five mills that we know of along a mile stretch of this river. The Historic Clifton Mill is the only one standing.

18. The Flour Bag Collection

The many flour bags you see hanging are from some of the many mills that no longer exist. We consider this our own little art gallery. You will not find bags like these on the shelves of your grocery stores. Many of these bags are 100 years old. The art work, color and detail is not found on bags of today. Many of them have catchy titles for their flour. The truth is that it is basically all the same flour, just catchy names that the mills took pride in telling the world that this was their flour.

Schedule a Tour

To schedule a tour to see the Historic Historic Clifton Mill and how it functions, call us at 937-767-5501 or fill out the form on the contact page. Groups will require additional time to plan your visit.

You can always stop in to see the mill from the outside at 75 Water Street, Clifton, OH 45316

Don’t forget our restaurant and store when you stop in!

1. The Leffel Water Turbine

The Leffel Turbine is named after James Leffel who founded The Leffel Turbine company in Springfield, Ohio in the year 1861. When this area of the mill burned in 1869, the water wheel was destroyed and since the turbine was relatively new and more powerful, it was installed. The mill’s owners at the time were the Armstrong family.

Until then the Historic Clifton Mill used an under shot water wheel, which simply means the water ran behind the lower back side of the wheel. The water wheel that most people think of when they think of old mills is called an over shot wheel.

The turbine at Historic Clifton Mill gets its water supply from a mill race, which is simply a small stream or creek that is made by cutting a channel and diverting water held back by a dam. The Leffel turbine creates almost 300 horse power at 900 RPM. Water from the mill race enters the turbine from the top tube. It passes through valves and paddles which spin them around. The paddles are attached to a piece that holds the main shaft, so when the paddles spin, the shaft spins. The water is discharged through the draft tubes at the bottom. It is these draft tubes which help give the turbine its power or torque. The pull of the water falling down the draft tubes give it more power. The turbine also creates a strong suction from the smaller pipe in the front. This suction power was used in the early days to help vacuum out the mill. On the back side of the turbine there was a strong push of air which was used to cool the place down by blowing the constant air over a block of ice. The water power was also used for the millers work bench area to turn the lathe and table saw. This is pure clean power, the water is not heated or treated in any way.

3. The Pancake Mixer

The pancake mixer was built in the 1800’s. The mixer tumbles and blends all the ingredients that the miller puts in to make our mixes. It has the capacity to do 500 lbs. at a time and takes about 15 minutes to complete this operation. From the mixer the product is moved up by the bucket elevators to the bagging area.

4. The Generator

The Generator was installed in 1908. From 1908 to 1938 the generator ran 24 hours a day to provide electricity for many of the homes of Clifton, Cedarville and Yellow Springs for $1.00 a month.

5. Red Meadows Mill

The 20 inch Red Meadow Mill is the corn grinding mill. It is a Sprout and Waldron French Burr Mill, built in 1889. It has a pair of 20 inch burr stones. French refers simply to where the stone (granite) was quarried. The term burr is the way the stone is cut to help it grind. The stones are inside the red metal housing. The corn enters through the center. One stone is stationary and the other is rotating. The grain is crushed as it moves to the outside of the stones. This mill can grind up to 800 pounds an hour.

6. Gray Meadows Mill

The gray grinder is for our wheat and rye grinding. By adjusting the gap between the two vertical stones, the miller can make cracked wheat or whole wheat at various degrees of coarseness. This Meadows Mill was built in the early 1900’s. The stones inside are 24 inch French Burr stones and can grind up to 1000 lbs an hour.

7. Bulk Corn Product Bagging Area

In this area, the corn is bagged. It is sifted and separated into 3 main products. The chute in the center is where corn meal comes down to be bagged. Corn meal is made from the center of the grain. It may look like it has black specs in it but this is the corn germ, the part of the seed that has the best nutritional value for you. The third chute is for the corn bran. Corn bran has a lot of the hard shell it in and is usually sold off as feed.

8. Woodward Governors

The Woodward governors were installed when theturbine was installed in the late 1800’s. The function of the governors is to control the RPM of the mill to make sure it is running at a good constant speed with enough power to keep grinding. If one set of stones is in use grinding corn and the miller wants to grind wheat on another set of stones at the same time the governors will automatically open up the water gates on the turbine to allow more water to enter the turbine. We still rely on this piece of equipment and it is built to last. When the round handle is turned towards you the mill starts up. It is one of the first things the miller uses.

9. Belt Bucket Elevators

The belt bucket elevators are used for many purposes. These square shafts run from the bottom of the mill to the top floor. They help move the grain to the holding bins for storage and move grain to the grinding area. They also move the ground flour and meal to the sifting, mixing and bagging areas. The belts are moved by the water power that drives the main shaft in the basement.

10. Bulk Bagging Area

In this area we bag up 25 and 50 pound bags of our whole wheat, cracked wheat and rye flour that is ground in the gray mill stone. The products in this area are whole grain. That means that it is not sifted, that the whole grain is in there. For example our whole wheat flour has wheat germ and wheat bran mixed in with the wheat flour. This is the healthiest type of flour. The bread flour and whole wheat pastry flour are ground much finer and are not coarse compared to whole wheat or cracked wheat.

11. The Rotex Sifter

This sifter has been in use for almost 100 years. It is the second sifting phase for the corn. The corn meal and corn flour that were separated from the case sifter above enter the rotex sifter. The rotex sifter then agitates back and forth moving the material over a set of screens, each a different size. One size is very small so only the corn flour passes through. The corn meal then drops through the screen with the larger holes. Each screen level leads to a chute that takes it to the lower floor.

13. The Case Sifter

This sifter is what the mill uses for the first step in the separating process. Once the corn has been ground the buckets and elevators move the ground material into the sifter where the flaky bran and corn hulls are removed. This is done by the material moving across a cylinder covered with screen. The hulls are too big to fit into the holes of the screen. The cylinder spins around letting the corn meal and flour drop through while the hulls are pushed over and down a chute.

14. The Cyclone Cleaner

The cyclone cleaner is used to catch the pieces of corn cob and corn stalk that may be in with the corn when it was brought into the mill from the fields. The grain would move across an area of large metal screens and drop down into a chute that leads to the storage bins. The water power from the mill would spin a set of wooden blades inside the cone shape. This would create a strong draft and suction that would remove dust, dirt, cob and stalks early in the storage process.

15. The Old Stones

Inside this wooden case are the original stones that the mill used back in 1802. They are almost 2 tons in weight and are 48 inches wide. These stones are unique because of the way they are put together. The stones are pieced together like a puzzle to help form a round wheel. The pieces are from the ballast of some of the early ships that came here. There were no quarries then so they used the rock ballast to make the grinding stones. These stones are also made of granite. The stones are set in a horizontal position. The corn drops into the center and is ground up by the weight and motion of the top stone, the “runner”, while the bottom stone remains stationary. The top stone is called the “runner” because it moves while the bottom stone is stationary. These stones are able to grind 400 to 500 lbs of grain. The amount of corn that can enter the stones is controlled by what is called the shoe, which sits on top of the wooden case. As the stones grind at a constant level the vibration is also fairly constant. The vibration helps the shoe shake some corn down to the stone. A small rope on the shoe helps determine how much corn the shoe will drop into the stones. You can see the shaft that powers these stones in the floor below. The miller would check the degree of coarseness by moving the little door at the bottom of the stones base. The miller would open it, stick his hand in and squeeze it to see how much flour there was. He can adjust the stones to make it more or less coarse. Move stones close together and get finer flour, move apart and get coarse.

16. The Hopper Scale

This scale has a dual purpose. It is a small temporary holding bin that is also a scale. This allowed both the farmer and the miller to agree on exactly how much grain there was to store and grind. Once weighed the grain drops to the bottom hole and is moved by belts and buckets either to the large storage bins or redirected to the grinding area.

17. The Main Beams

The main beams that you see in the mill are from trees that were cut down right here. The early builders used local trees to build all of the mills along this river. There were at least five mills that we know of along a mile stretch of this river. The Historic Clifton Mill is the only one standing.

18. The Flour Bag Collection

The many flour bags you see hanging are from some of the many mills that no longer exist. We consider this our own little art gallery. You will not find bags like these on the shelves of your grocery stores. Many of these bags are 100 years old. The art work, color and detail is not found on bags of today. Many of them have catchy titles for their flour. The truth is that it is basically all the same flour, just catchy names that the mills took pride in telling the world that this was their flour.